Meet Creo Prismatic, a Virtual Milling ‘Specialist’ for Prismatic Production Machining

Download a 30-day Trial of Creo 7.0!

By form submission, you agree to the Terms of Service

ABOUT

Creo Prismatic:

Easy-to-Use High-Speed Machining!

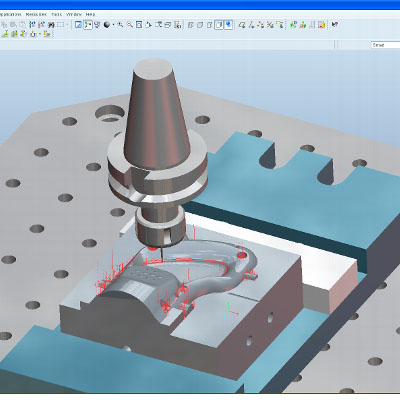

Not all CAM solutions are created equal. Some tools emphasize ease-of-use, others promote cost advantages. The best solution for directly machining product parts on production lines would be price competitive, feature-rich, yet, unlike other CAM tools, it would enjoy seamless compatibility with the design.

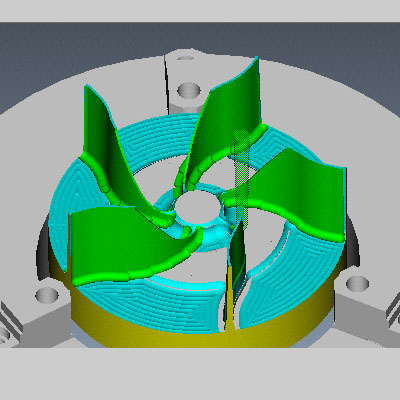

This is PTC Creo Prismatic and Multi-Surface Milling Extension. A virtual milling “specialist” for prismatic machining, it greatly and affordably increases NC productivity and improves manufacturing tooling and factory equipment design processes.

Easy-to-use, feature-rich, and seamlessly integrated with design–Creo Prismatic and Multi-Surface Milling is a virtual milling ‘specialist’ for prismatic production machining. Put Creo Prismatic to work for you.

-

MACHINING PROCESSES

MACHINING PROCESSES

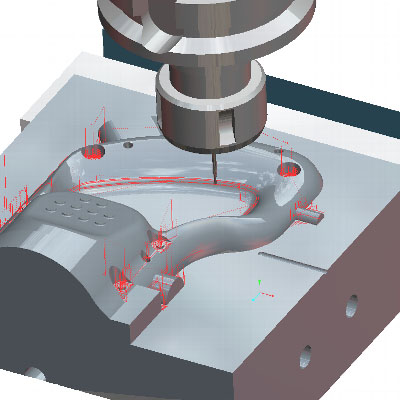

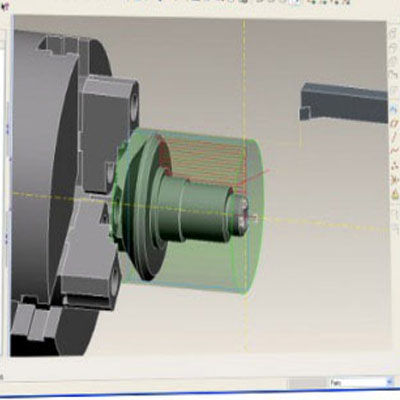

Machining processes shape metal by the controlled removal of material. Prismatic machining cuts a 3D shape in one ‘go’. Milling, one of the most commonly used, removes material. Turning is much as it sounds: rotating the part against a machine known as a lathe. Wire Electrical Discharge Machining (EDM) uses electrically charged wire to vaporize material rather than cutting it by traditional methods.

-

CNC MACHINES

CNC MACHINES

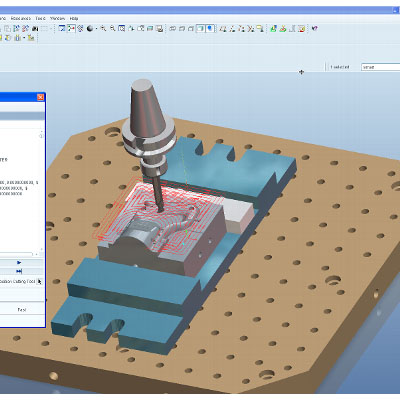

CNC (computer numerical control) machines are machines guided by CAD data rather than by human beings. Machining is used when parts require tight tolerances and finishes. Being able to control these processes – and integrate them with CAD software – is critical to efficiency, the precision of your parts, and the quality of your product.

-

WELL DOCUMENTED

Features

Creo Prismatic - Complete Milling

Images & Videos

Design Examples Using Creo Prismatic

Select Category

-

Annotation

AnnotationExtraction of manufacturing annotation features.

-

Library

LibraryContains a tool and fixture library.

-

Documentation

DocumentationManufacturing process documentation Pro/PROCESS for manufacturing.

-

Generator

GeneratorGPOST: NC post-processor generator.

-

Simulation

SimulationVERICUT for Creo: NC simulation.

-

-

-

-

-

See More Videos on Creo Prismatic